EPM improves leak detection, operational efficiency and long-term planning with TaKaDu

Background

Empresas Públicas de Medellín (EPM), founded in 1956, provides drinking water, residual water, energy, gas and other services to residents of Medellin, Colombia as well as surrounding areas in the Antioquia Department and beyond. Its water network has 213 DMAs in 94 zones serving more than 4 million people.

Goals

As its network, infrastructure and staff grew over the years, so did the amount of data it was collecting. Handling visual information manually became more complex and time consuming. EPM’s field teams struggled to manage the many leak and asset failure events and mostly operated in reactive mode following consumers’ reports of water bursts. The utility needed a more efficient workflow for identifying and assigning such events, including better prioritization and planning.

“For example,” says Carlos Humberto Palacio Sierra, Head of the Water Losses and Wastewater Control Unit at EPM, “sudden changes in signals from the various sensors were monitored by the SCADA system, but no analysis was done. Management of the nightline was based on SCADA, as were leak searches. Once the nightline was graphed, the searches were planned. A separate application took the data from the SCADA and generated a graph of the minimum nightline.” That process was slow and labor-intensive, resulting in high water losses. And, as EPM’s network grew, it became harder to scale up nightline management.

EPM realized it needed a better way to achieve more with its existing resources. This meant a better way to analyze information, and to make searching for leaks more systematic and efficient rather than reactive. It wanted a system that would automatically indicate events with more information and understanding than what SCADA can provide. The system also needed to be simple to use (and effective) to ensure that EPM’s personnel would adopt it.

Solution

EPM considered varied technologies and solutions and ultimately opted for analytics software. Following a successful pilot that produced good results, EPM chose the TaKaDu Central Event Management (CEM) solution. It began using TaKaDu in August 2019. Initially, TaKaDu was introduced to a large group of key people within the organization to raise awareness of it. Subsequently, specific users were identified and their roles and interactions with third parties were established. An efficient workflow was developed from there. No changes were required to EPM’s infrastructure in order to implement the TaKaDu CEM.

Results

TaKaDu provides EPM with a more holistic picture of its network and water management. With 24/7 automatic detection of events, including early-stage leaks when no other indicators are present, ongoing prioritization is now possible. Asset failures such as pressure, water quality, reservoir level, faulty meters and communication failures are caught earlier. This enables EPM to deal with them more efficiently and with fewer resources. It can make many small repairs to fix small leaks across its large network to reduce physical losses, rather than incurring the substantially higher costs of fixing major bursts.

As Carlos notes, “We have greater control of the nightline across the entire system. Thanks to TaKaDu, we can now prioritize failure events according to the importance of the signals.” Ultimately, this all contributes to an overall reduction in water loss across EPM’s network.

After working with TaKaDu for some time and fixing leaks identified through the system, EPM’s minimum nightline stabilized. Carlos notes that a lower and more stable minimum nightline enables long-term planning for fixes in the field to decrease losses even more.

Workflow efficiency and inter-departmental communications have also improved dramatically. EPM can now properly manage events throughout their lifecycle and perform activities such as sharing events with colleagues, auto-logs of the changes, writing comments and attaching files.

Today TaKaDu is part of EPM’s daily routine, across departments. The system automatically creates alerts and emails messages to designated users. The Integrated Operations unit assigns the alerts to the Loss Control team, where operators drill down into the events, identify issues and prioritize them based on the values and criticality, according to the sector. Activities are then assigned to the Equipment Maintenance and Network Maintenance units according to the event type. Prior to closing the event, automatic verification of the fixes in the field confirm that the problem has been solved.

With this daily use, “the objective of having greater visibility at the time of making operational decisions has been achieved,” says Carlos. With that, he notes, “Every month or so, EPM management looks at KPIs to understand the performance of people, processes and technology (PPT). Based on that, operational plans are adjusted to optimize them.” And over time, benefits have only improved. “By cross-referencing changes in flow rates to changes in pressure, we’re able to identify the source of the problem more easily. As we gain more and more experience, we are better able to identify problems and we know how to address them more effectively,” he continues.

SPECIFIC EVENT HIGHLIGHT

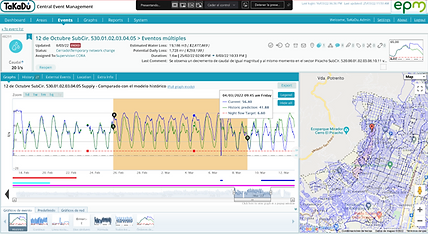

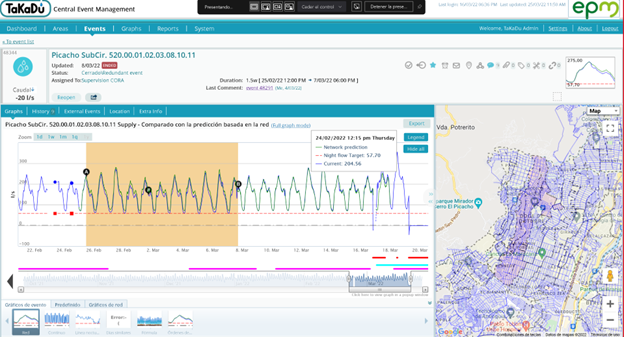

TaKaDu speeds response to open boundary valve

Carlos points to a specific example when the TaKaDu system detected an increased flow event running at 20 l/s in a sub-circuit known as 12 de Octubre. The Operations team analyzed the event and, noticing that the night values were high, suspected a leak. A field team was sent out to track it down.

After the field team combed the sector without finding the leak, EPM turned to TaKaDu to help it interpret the graph. Analysis of the pressure data and the behavior of the flow indicated that the situation was due to a boundary valve in a bordering sector. EPM’s Loss Control unit then searched for a corresponding negative flow event of equal magnitude. An event was found in the Picacho sector bordering the southern part of the 12 de Octubre sector. The field team then checked just the boundary valves between these two sectors and was able to confirm that there was indeed an open boundary valve, apparently left open after maintenance activities. Once the boundary valve was closed, both sectors returned to normal, which was reflected and verified in TaKaDu.

The Operations team took away several important lessons from this event, enabling it to avoid overbroad searches in the future. This allows timelier responses, effectively reducing water loss and improving service quality.

The view ahead

Going forward, EPM plans to increase the sectorization of its network and expand telemetry coverage to enable it to get even more value from TaKaDu. “The benefits demonstrated by TaKaDu allow a justified investment in new telemetry and in sub-sectoring to reduce the route of leak detection teams,” says Carlos.

With water loss reduction and operational efficiency achieved, EPM is now evaluating integration of its work orders with TaKaDu to enable even greater visibility into the activities of other departments, for more informed decisions based on the additional insight.

EPM is also considering a pressure management project and a network reorganization project to further facilitate the field interventions that allow overall better operation of the network and consequently will extend the lifespan of assets.

Overall, Carlos concludes, “TaKaDu is a very versatile and easy to learn tool which we would definitely recommend. The system is reliable and identifies problems with very few false positives. This does not always mean a simple and quick solution. But TaKaDu assures us of the existence of an anomaly that is identifiable, delimited and measurable in the field, which we can work with.”

By working with TaKaDu, EPM has signifantly advanced its operational excellence. With the ability to identify problems faster and more accurately, EPM is incurring less collateral damage to assets and is investing fewer resources in repairs, while also reducing water loss.

AT A GLANCE

GOALS

- Detect and locate leaks more systematically and efficiently

- Improve operational efficiency and reduce stress on field teams

SOLUTION

- TaKaDu CEM has been deployed at EPM since 2019

RESULTS

- A more holistic view of the water network and management

- Improved operational efficiency and more streamlined workflow

- Early detection of events reduces time and material costs for fixes, minimizes collateral damage and water loss

- Better long-term planning helps optimize resources

Join the Digital Journey Today!